Raven Farms: Running More Acres on a “Skeleton Crew” With John Deere Operations Center

Published: February 13, 2026

Updated: February 13, 2026

|

Farm and Agriculture

When you farm across three counties with a small team, every pass, every minute, and every decision matters. That’s the reality for Raven Farms, a corn and soybean operation spread across Clark, Champaign, and Miami counties in Ohio. Mia Grimes and Derek McClennic have built on Mia’s late father’s legacy by leaning hard into John Deere technology—especially Operations Center—to gain the control and efficiency they need to keep the farm moving forward.

Building on a Legacy of Technology

Long before Raven Farms existed by name, technology was already part of the operation. Mia’s dad always made sure the farm had the latest tools, even if they weren’t always used to their full potential. When he passed away in 2013 and Derek joined the operation, Mia and Derek made a conscious decision: they weren’t just going to own technology—they were going to implement it to drive how they farm.

Today, Raven Farms runs a roughly 50/50 corn and soybean rotation and manages acres across three counties with what they describe as a “skeleton crew.” That staffing reality pushed them to refine their systems and rely on John Deere Operations Center as the digital backbone of their operation.

Turning Data into Daily Decisions

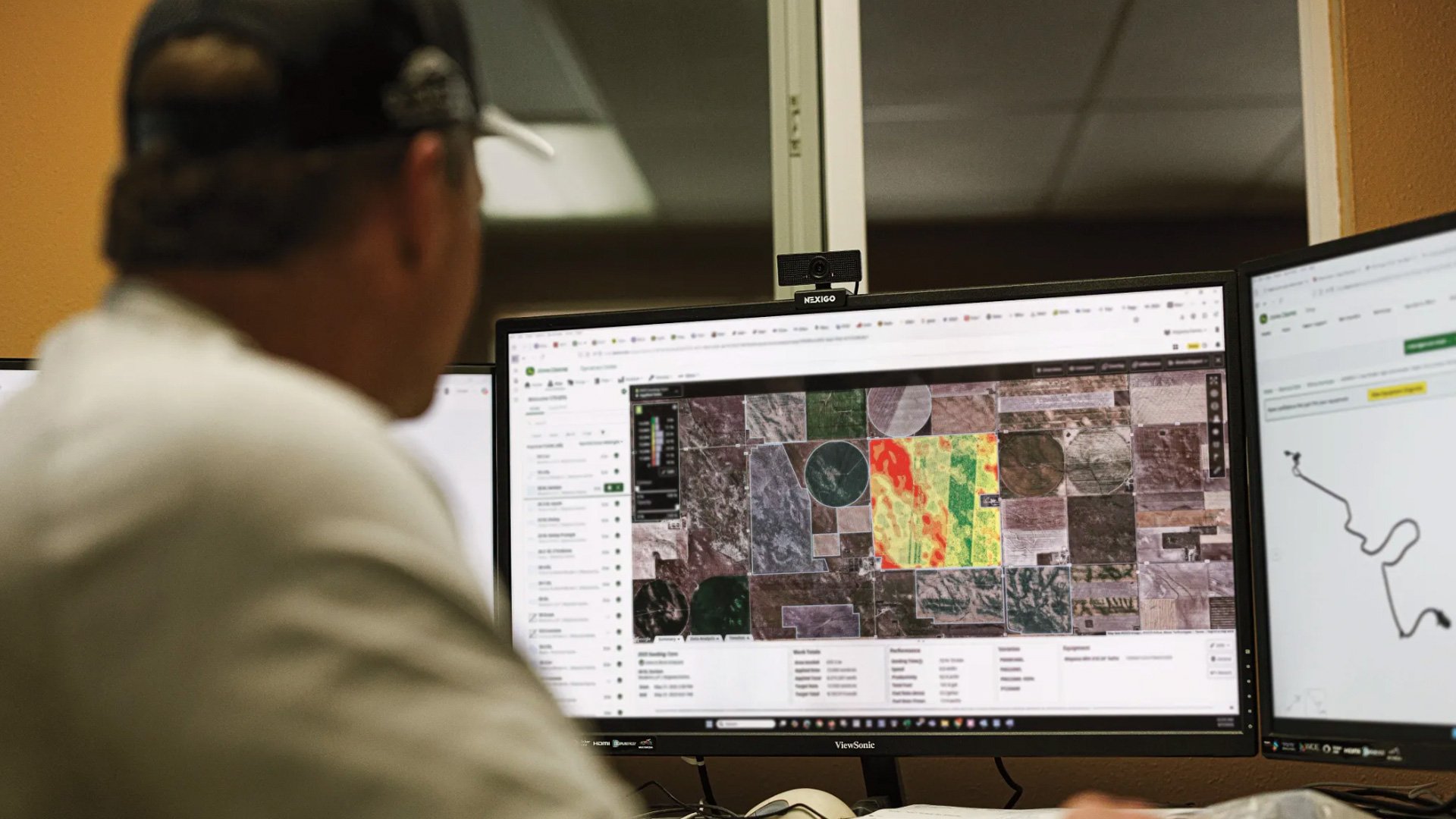

From the beginning, Operations Center has been central to how Raven Farms runs. It started as a way to collect data, but as the platform has improved, Mia and Derek have used more of its capabilities to make better-informed decisions in real time.

They use machine and vehicle connectivity to see where equipment and trucks are during busy seasons like harvest and spraying. Instead of constant phone calls to check location and timing, they can simply pull up the information. That saves time, cuts down on distractions for drivers, and helps the team stay focused on the work in front of them.

The same data that keeps everyone on the same page also feeds into their agronomic decisions. With years of field information at their fingertips, they can tailor how they plant and apply inputs to each acre.

AutoPath, Prescriptions, and ExactApply in the Field

One of the biggest game-changers for Raven Farms has been the combination of AutoPath, variable-rate prescriptions, and ExactApply.

Using AutoPath, they generate guidance lines from the planter and carry those same lines through spraying and side-dress passes. That consistency means more accurate traffic patterns, less overlap, and fewer skipped areas. For Derek, it has transformed side-dressing and spraying into more efficient, precise operations.

On the agronomy side, Mia builds variable-rate prescriptions for both seed and nitrogen. They can dial in rates for each acre, trimming unnecessary inputs along fence rows, waterways, and low-response zones. That approach helps them protect their bottom line while making sure high-potential areas get what they need.

ExactApply on the sprayer adds another layer of control. With nozzle-level management, they can maintain accurate rates across varying speeds and field conditions, which is especially important when timing is tight and windows are narrow. For Raven Farms, spraying is one of the most critical jobs they do, and having this technology working together means they can make the most of every suitable day.

Work Orders That Keep the Crew Moving

With a small team and a lot of ground to cover, Raven Farms can’t afford delays at the field entrance. That’s where work orders in Operations Center make a difference.

Before equipment ever pulls into a field, Mia builds work orders that include products, varieties, and prescriptions for each job. When Derek or another operator arrives, they can select the correct work order, unfold, lower the planter or boom, and get to work without manually entering every detail.

The same process carries over from planting to spraying. Having work orders prepared ahead of time removes guesswork, reduces the chance of errors, and keeps the team focused on the job instead of the setup. It’s a simple workflow shift that adds up to major time savings across a season.

Better Records, Less Risk

Beyond efficiency and input savings, Operations Center has become a powerful recordkeeping tool for Raven Farms.

With weather information and application details captured automatically, they no longer rely on handwritten notes at the end of a long day. When questions arise from regulators or neighbors, they can pull detailed spray records and share exactly what was applied, where, and under what conditions. That documentation has already helped them address and resolve claims, providing peace of mind as well as compliance.

Remote display access adds another dimension to uptime. Instead of waiting for someone to drive out with a laptop or guessing at an issue over the phone, support can log in, see what the operator sees, and help troubleshoot quickly. Getting the right parts to the field the first time and avoiding unnecessary trips has played a role in making this past year one of the most efficient seasons they’ve ever had.

Doing More With the Same Crew

For Mia and Derek, the story of Raven Farms and John Deere technology is really a story about making the most of what they have: their people, their time, their machines, and their data. By fully embracing Operations Center, AutoPath, ExactApply, and variable-rate prescriptions, they’ve turned a multi-county, skeleton-crew operation into a highly organized, data-driven farm.

Instead of chasing problems and paperwork, they’re able to focus on timing, execution, and long-term decisions that move the operation forward. It’s proof that when technology, people, and processes are aligned, you don’t always need more hands—you just need better tools and a clear plan for how to use them.

Subscribe to our Newsletter

Recent Posts

- Raven Farms: Running More Acres on a “Skeleton Crew” With John Deere Operations Center

- Do More For Less: Versatile Compact Construction Equipment

- John Deere 1025R vs 2025R: How to Choose the Right Compact Tractor for Your Property

- Winter Mower Must-Do: The Simple Service That Saves Your Spring

- December 2025: Koenig’s 12 Days of Giveaways Bring Extra Holiday Cheer